Ductile Iron / Cast Iron Pipe

Posted on

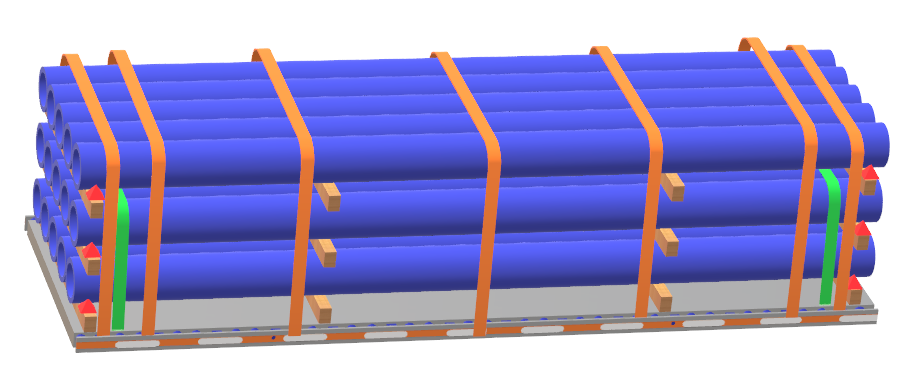

- These loads are commonly loaded in two sections.

- Each section of pipe must have a minimum of 4 straps.

- Placing straps next the dunnage will create more stability.

- Placing Belly straps on the load is recommended.

- Gaskets and lube may accompany load. Gaskets must be in secure packaging and strapped down to the trailer. The Lube can be placed in side box for secure transportation.

- Note: When strapping and unstrapping load, always check for unsecure chocks. If packaging is not sufficient, notify shipper / loaded. If additional assistance is needed, contact Safety Department.

Back to Top

Steel Pipe

Applies to any cargo over 10ft long

- Two tie-downs must be placed over the first 5ft of the load.

- Place two tie-downs over the rear 5 ft of the load.

- Place one tie-down every eight feet between the front and rear sets of tie-downs.

- If a load is 3 tiers high or more, belly straps must be used to secure the second layer (green straps on figure 1.)

Points to Remember:

- When hauling pipe remember that it must be blocked to prevent rolling during transit. This is generally done with the use of wooden or plastic chocks (see the red chocks in figure 1). A driver may have to provide his own chocks at certain locations. If you don’t have them, be sure to ask.

- Remember proper securement means every piece must have direct downward pressure from a tie-down, a block of dunnage, or another piece of cargo.

| Figure 1: A load of stacked and stripped pipe secured with 4-inch straps. Notice the chocks (red) on the front and rear dunnage. There is also a belly strap (green) over the second tier of the load. Over the top there are two straps over the front and rear five feet of the load. Then other straps every eight foot in between. |

Back to Top

Pipe- Pyramid Configuration

Posted on

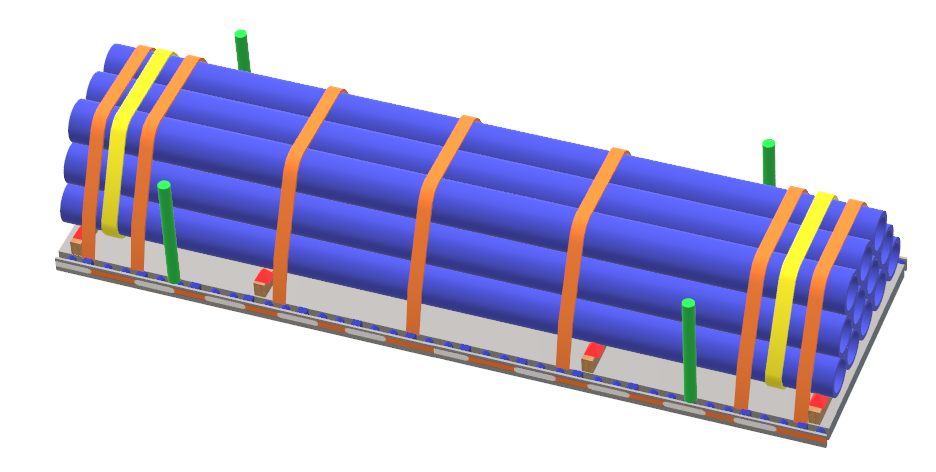

- Pipe stakes must be placed on the trailer and chained at the base. (Green in Figure 1)

- Dunnage at the base of the load must have blocking to prevent rolling.

- Once the pipe is loaded the load should be choked with two 2-inch portable straps. One on each end. (yellow strap in Figure 1).

- Load is then secured with two tiedowns in the first 5 feet of the load, then one strap every 8 foot for the remainder of the load.

- An additional strap should be placed at the rear of the load within the last five feet of the load.

Points to Remember:

- Pipe stakes are required and must be chained at the base.

- Be sure the blocking on the dunnage is nailed in properly.

- Pipe can roll when the straps are released. Be sure to watch the load when taking the straps off before unloading. Release the strap to the forward most or rearward most part of the load last so that you can get away from falling cargo.

- Remember proper securement means every piece must have direct downward pressure from a tie-down, a block of dunnage, or another piece of cargo.

| Figure 1: Pyramid pipe load showing the chocks (red) pipe stakes (green), choke strap (yellow), and securement (orange) over the load. |