Applies to any cargo over 10ft long

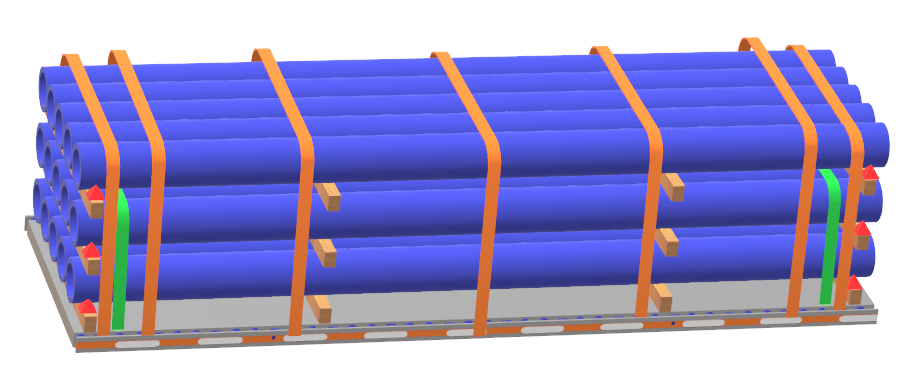

- Two tie-downs must be placed over the first 5ft of the load.

- Place two tie-downs over the rear 5 ft of the load.

- Place one tie-down every eight feet between the front and rear sets of tie-downs.

- If a load is 3 tiers high or more, belly straps must be used to secure the second layer (green straps on figure 1.)

Points to Remember:

- When hauling pipe remember that it must be blocked to prevent rolling during transit. This is generally done with the use of wooden or plastic chocks (see the red chocks in figure 1). A driver may have to provide his own chocks at certain locations. If you don’t have them, be sure to ask.

- Remember proper securement means every piece must have direct downward pressure from a tie-down, a block of dunnage, or another piece of cargo.

| Figure 1: A load of stacked and stripped pipe secured with 4-inch straps. Notice the chocks (red) on the front and rear dunnage. There is also a belly strap (green) over the second tier of the load. Over the top there are two straps over the front and rear five feet of the load. Then other straps every eight foot in between. |

- When hauling Steel beam, angle, etc…. we need to prevent forward movement by means of x-chains, header board, or building a bulkhead. Chains should be utilized at a minimum on the front, center, and rear these loads unless stated otherwise. Any straps must have edge protection.